An integrated control unit is a compact system that manages and coordinates multiple functions within a device or machine. It acts as the brain of modern systems, ensuring smooth operation by processing data and executing commands. You can find these units in various technologies, from cars to smart devices. By streamlining processes, they improve efficiency and enhance performance. Their ability to handle complex tasks makes them essential in today’s fast-paced, technology-driven world.

An integrated control unit works like the brain of machines. It handles many tasks to make them work better and faster.

These units make systems easier by merging many controllers into one. This lowers mistakes and makes setup simpler.

Integrated control units can change and grow, so they fit many uses, like in cars or smart gadgets.

They process data quickly, helping them decide fast. This makes them more reliable and reduces delays.

As tech improves, these units will get smaller and smarter. They will help create new ideas in AI, robots, and IoT.

An integrated control unit is a centralized system that manages multiple functions within a device or machine. Its primary purpose is to streamline operations by integrating various components into a single unit. This reduces the need for separate controllers, making systems more efficient and easier to manage. For example, in vehicles, the integrated control unit oversees critical components like the motor controller and Battery Management System (BMS). It ensures these parts work together seamlessly, improving overall performance and reliability.

Core Function | Description |

|---|---|

The unit centralizes control functions, managing components like the motor controller and BMS. | |

Communication Facilitation | It enables smooth communication between different components for harmony. |

Performance Optimization | It adapts performance to available power and user requirements. |

An integrated control unit offers several advanced features that set it apart. It can process large amounts of data in real-time, enabling quick decision-making. Its ability to communicate with multiple components ensures smooth coordination. Many units also include self-diagnostic tools, which help identify and resolve issues before they escalate. These capabilities make the unit essential for modern systems that demand high efficiency and reliability.

You’ll also find that these units are designed to be adaptable. They can scale to meet the needs of different applications, from small devices to large industrial systems. This flexibility makes them a valuable asset in various industries.

Standard control units typically manage a single function or component. In contrast, an integrated control unit combines multiple functions into one system. This integration reduces complexity and improves efficiency. For instance, a standard unit in a car might only control the engine, while an integrated unit manages the engine, transmission, and other systems simultaneously. This holistic approach ensures better performance and reduces the need for multiple controllers.

Another key difference lies in communication. Standard units often operate independently, which can lead to inefficiencies. Integrated units, however, facilitate seamless communication between components, ensuring they work together harmoniously. This makes them a superior choice for modern, interconnected systems.

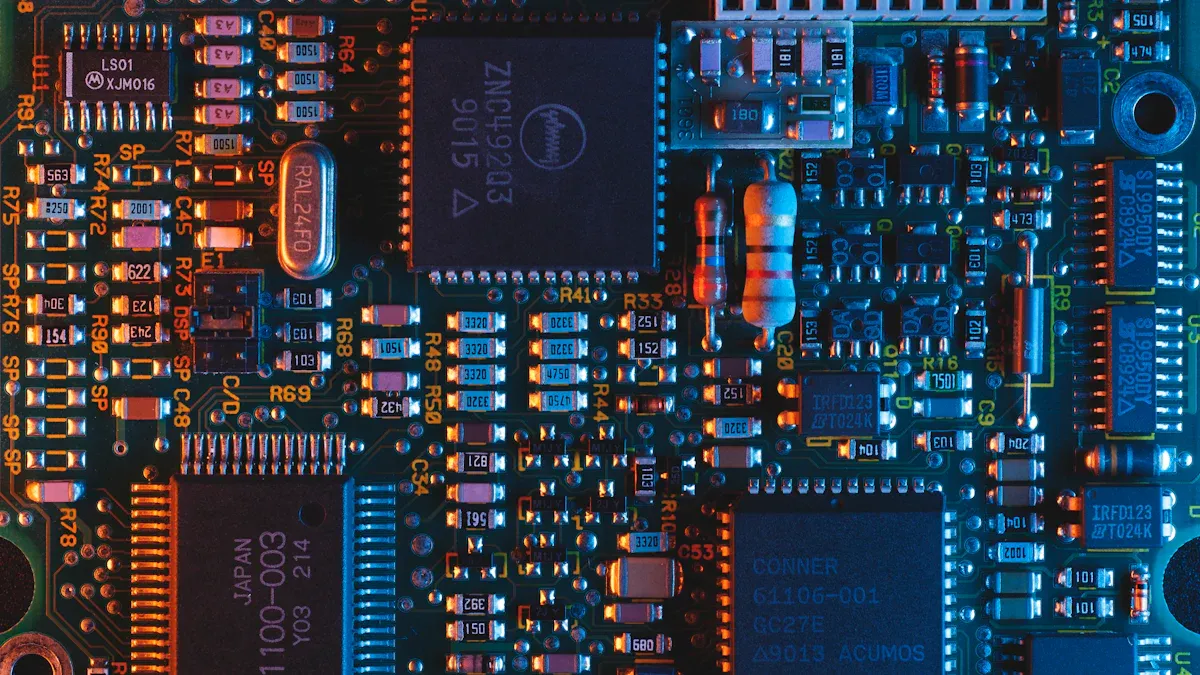

An integrated control unit relies on several key components to function effectively. Each plays a specific role in ensuring the system operates smoothly. At its core, you’ll find a microcontroller or processor. This acts as the brain, executing commands and processing data. Sensors and actuators work alongside it, gathering real-time information and performing physical actions based on the unit’s instructions. For example, in a vehicle, sensors monitor engine performance, while actuators adjust fuel injection or braking systems.

To understand how these components come together, consider the steps involved in designing a schematic:

Define the system’s purpose and scope.

Identify the main components, such as processors, sensors, and actuators.

Connect these components logically to ensure seamless communication.

Label and annotate the schematic for clarity.

This structured approach ensures every component contributes to the unit’s overall functionality.

The integrated control unit manages a variety of processes to keep systems running efficiently. It monitors operational states, such as "in-control" or "out-of-control," and takes corrective actions when needed. For instance, minor repairs might restore normal operations, while major repairs address critical failures. The unit also optimizes performance by determining the best sampling intervals and control limits.

Aspect | Description |

|---|---|

Model Type | Integrated Maintenance and Statistical Process Control Model |

States | In-control, Out-of-control, Failure |

Maintenance Actions | Minor repairs for in-control; major repairs for failure |

Optimization | Adjusts sampling intervals and control limits for peak efficiency |

This table highlights how the unit balances maintenance and optimization to ensure reliability.

Communication is vital for an integrated control unit to function. It connects various components and ensures data flows seamlessly. Routers and hubs facilitate this communication by forwarding data packets and linking devices. Firewalls add a layer of security, monitoring traffic to prevent unauthorized access. These interconnected systems form a network that allows the unit to share data and execute commands efficiently.

Data flows between storage locations and applications.

Network diagrams illustrate internal and external connectivity.

Systems communicate to maintain harmony and share critical information.

This interconnected design ensures the unit can adapt to complex systems, making it indispensable in modern technology.

An integrated control unit significantly boosts efficiency and performance by streamlining operations. It centralizes control, reducing delays caused by fragmented systems. You benefit from faster decision-making as the unit processes data in real-time. This proactive approach ensures that potential issues are detected early, minimizing downtime and improving overall reliability.

Several studies highlight the measurable advantages of using these units:

Cost Efficiency: Optimized processes reduce operational expenses.

Enhanced Asset Performance: Proactive management improves asset utilization.

Regulatory Compliance: Real-time updates help meet complex regulations effortlessly.

By integrating multiple functions into one system, the unit eliminates redundancies and ensures seamless communication between components. This results in smoother operations and better resource utilization.

The integrated control unit simplifies system design by combining multiple controllers into a single, cohesive unit. This reduces the need for separate hardware, making systems easier to manage and maintain. You’ll find this especially beneficial in applications like automotive systems, where managing multiple independent controllers can become overwhelming.

This simplification also reduces wiring and connections, which lowers the risk of errors during installation or operation. With fewer components to manage, you can focus on optimizing the system’s performance rather than troubleshooting complex setups. The streamlined design not only saves time but also reduces costs associated with maintenance and repairs.

Integrated control units excel in scalability and adaptability, making them suitable for a wide range of applications. They can handle increased workloads without compromising performance. For instance, as your system grows, the unit can scale vertically by adding resources like memory or processors. Alternatively, it can scale horizontally by incorporating additional computing units to distribute the load.

Metric Type | Description |

|---|---|

Scalability | Handles increased load without performance degradation. |

Vertical Scalability | Adds resources like memory or processors to improve performance. |

Horizontal Scalability | Distributes load by adding more computing units. |

Transaction Growth | Scales with the growing number of transactions or content. |

Flexibility | Adapts to various devices, platforms, or operating systems. |

This adaptability ensures that the unit can meet growing user demands, optimize resource allocation, and enhance system performance. It also helps you plan for future growth while mitigating risks like downtime during heavy loads. Whether in industrial automation or IoT ecosystems, the integrated control unit proves to be a versatile and reliable solution.

Integrated control units play a vital role in modern vehicles. They manage multiple systems, such as engine control, transmission, and advanced safety features, ensuring seamless operation. These units also enable the integration of sensors like stereo cameras to monitor the surroundings. By combining data from various sensors, they identify objects, such as vehicles or traffic signs, and generate a trajectory for the car to follow. This process, known as sensor fusion, enhances safety and efficiency.

As autonomous driving technology advances, vehicles require more sensors and faster data transmission to handle the increased volume of information. Integrated control units meet these demands by processing data in real-time and coordinating complex systems.

The automotive market reflects the growing importance of these units. In 2022, the market size reached USD 99.39 billion, with a projected growth rate of 5.9% annually through 2030. This growth is driven by the demand for feature-rich vehicles, advanced software, and fuel-efficient systems.

Aspect | Details |

|---|---|

Market Size | Valued at USD 99.39 billion in 2022 |

Projected Growth Rate | Anticipated CAGR of 5.9% from 2023 to 2030 |

Key Drivers | Rising demand for feature-intensive vehicles, focus on advanced software features, safety systems, and fuel efficiency. |

Challenges | Operational issues in supply chain and need for digitalization in emerging countries. |

In industrial settings, integrated control units enhance automation and robotics. They coordinate robotics, artificial intelligence, and sensors to improve production efficiency. For example, in the automotive industry, robots equipped with these units enable faster and more precise assembly processes. Electronics manufacturers rely on them for assembling delicate components like microchips. In pharmaceuticals, they ensure compliance with strict quality standards during drug packaging.

Assembly automation integrates robotics, AI, and advanced sensors to reduce costs.

Robots in automotive production improve speed and precision.

Electronics manufacturing benefits from precise assembly of microchips and circuit boards.

Pharmaceutical automation ensures safety and quality in packaging.

These units streamline operations across industries, making them indispensable for modern manufacturing.

Integrated control units are at the heart of smart devices and IoT ecosystems. They enable seamless communication between devices, allowing you to manage your home or workplace effortlessly. For instance, smart thermostats use these units to learn your preferences and optimize energy consumption. By integrating AI and machine learning, they adapt to your habits, providing convenience and efficiency.

The demand for smart technologies continues to grow. Integrated control units support this trend by enabling devices to work together in harmony. Whether it's controlling lighting, security, or appliances, these units simplify your life while reducing energy costs.

Emerging technologies are reshaping how integrated control units function and expand their applications. You can see advancements in robotics, artificial intelligence, and edge computing driving these innovations. Companies like ARTERY Technology and Unitree Robotics are collaborating to develop intelligent robotics and motor control systems. These systems rely on integrated control units to manage decision-making, coordination, and real-time control.

Modern control units now include modules like sensing units and drive units. These modules enable high-degree-of-freedom joint control and multi-axis servo motor drives. For example, robotics equipped with these units can perform complex tasks with precision. This makes them ideal for industries like manufacturing and healthcare, where accuracy and efficiency are critical.

Future innovations focus on edge AI platforms. These platforms integrate microcontroller units (MCUs) with neural processing units (NPUs). This combination allows local inference and edge learning capabilities. You benefit from faster data processing and reduced reliance on cloud computing. Products like AT32F415 and AT32F435 are paving the way for these advancements, offering enhanced performance for next-generation applications.

Aspect | Details |

|---|---|

Collaboration | ARTERY Technology and Unitree Robotics |

Focus | Advancements in intelligent robotics and motor control systems |

Key Modules | Control unit, sensing unit, drive unit |

Control Unit Functions | Decision-making, coordination, real-time control |

MCU Products | AT32F415, AT32F403A, AT32F435, AT32M412 |

Applications | High-degree-of-freedom joint control, multi-axis servo motor drive |

Future Outlook | Development of edge AI MCU platform with NPU for local inference and edge learning capabilities |

These innovations promise exciting possibilities. You can expect integrated control units to play a key role in autonomous systems, smart cities, and advanced IoT ecosystems. As technology evolves, these units will become even more adaptable and efficient, driving progress across industries.

You can expect integrated control units to become smaller, smarter, and more efficient as technology advances. Miniaturization allows these units to fit into compact spaces while maintaining high performance. This trend is crucial for industries like healthcare and consumer electronics, where space-saving designs are essential. Additionally, modular designs are gaining popularity. They let you customize control units for specific applications, offering flexibility and reducing costs.

The following table highlights key trends shaping the future of these units:

Trend | Description |

|---|---|

Increased Automation | Growing automation across industries demands efficient control systems. |

Industry 4.0 Adoption | Smart control units enhance data exchange and operational efficiency in Industry 4.0 setups. |

Technological Advancements | Innovations make control units more advanced and cost-effective. |

Government Initiatives | Policies promoting automation and energy efficiency drive market growth. |

AI Integration | AI enables predictive maintenance and advanced control algorithms. |

Increased Connectivity | 5G adoption improves data exchange and remote monitoring. |

Modular Design | Customizable units provide flexibility for diverse applications. |

Miniaturization Improvements | Smaller, more powerful units save space and boost efficiency. |

These trends show how integrated control units are evolving to meet the demands of modern technology.

Integrated control units are essential for advancing AI and machine learning. They process vast amounts of data quickly, enabling real-time decision-making. For example, in healthcare, AI-powered control units assist in drug discovery and predict treatment outcomes. In finance, they help detect fraud and manage risks effectively. As AI becomes more prevalent, these units will play a larger role in supporting complex applications.

Recent advancements in processing technologies have further enhanced their capabilities. Specialized AI chips, like the one launched by NVIDIA in March 2024, improve the efficiency of AI computations. These innovations make integrated control units indispensable for industries relying on AI, such as robotics, autonomous vehicles, and smart cities.

While the future of integrated control units looks promising, you should also consider the challenges. One major hurdle is ensuring cybersecurity. As these units become more connected, they are vulnerable to cyberattacks. Developing robust security measures will be critical. Another challenge is managing the cost of advanced technologies. Smaller, more powerful units often require expensive materials and manufacturing processes.

On the other hand, these challenges present opportunities. For instance, investing in cybersecurity can lead to the development of safer, more reliable systems. Similarly, advancements in manufacturing techniques can reduce costs over time. By addressing these challenges, you can unlock the full potential of integrated control units and drive innovation across industries.

An integrated control unit serves as the backbone of modern technology, managing and coordinating multiple functions within a system. It simplifies operations, enhances efficiency, and adapts to various applications, from automotive systems to smart devices. You can see its impact in improving performance and reducing complexity across industries.

Looking ahead, this technology holds immense potential to drive innovations in AI, robotics, and IoT. By embracing these advancements, you can unlock smarter, more efficient systems that shape the future of technology.