Integrated control solutions combine hardware, software, and communication technologies to manage and automate processes seamlessly. These systems transform industries by enabling smarter operations. Their importance in 2025 cannot be overstated. For example:

The Automotive Integrated Control Panel Market is set to grow from $24.82 billion in 2025 to $39.47 billion by 2034.

Multi-Function Control Panels will rise from $2.26 billion to $4.9 billion within the same period.

This growth reflects the increasing demand for efficiency, innovation, and automation across sectors.

Integrated control solutions use tools and programs to make work easier.

These systems save money by using resources wisely, up to $1.5 million in three years.

Watching systems in real-time and using automation makes work safer by spotting problems and lowering mistakes.

Industries like factories, hospitals, and energy companies work better with these solutions, improving rules and output.

Using smart tech like AI and IoT helps businesses grow and work better in the future.

Integrated control solutions are systems that seamlessly combine hardware, software, and communication technologies to manage and automate processes. These solutions are designed to simplify operations, enhance efficiency, and improve decision-making across various industries. By integrating multiple components into a unified system, they eliminate the need for separate, disconnected tools, making operations more streamlined and effective.

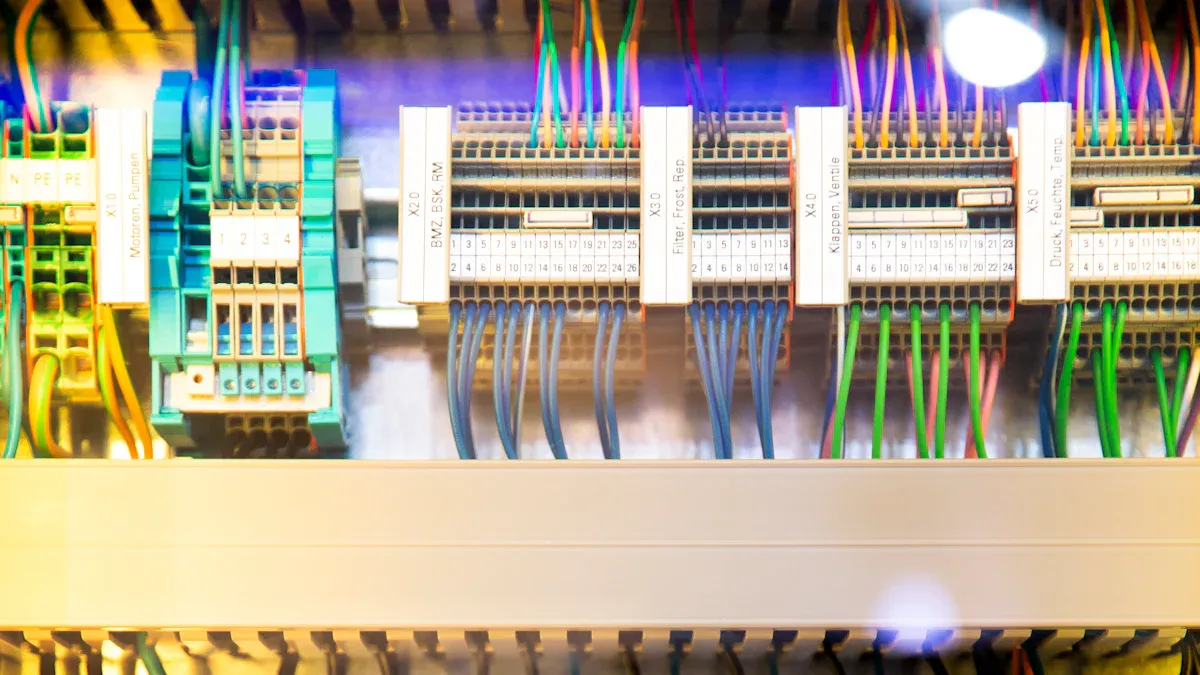

Integrated control solutions rely on a combination of hardware, software, and communication technologies. Each component plays a vital role in ensuring the system operates smoothly and efficiently.

Component Type | Specific Components |

|---|---|

Hardware | Microcontrollers, Microprocessors, Sensors, Actuators, Power Supply Units |

Software | Operating Systems (RTOS), Firmware, Embedded Software, Application-Specific Software |

Communication | CAN, Modbus, Ethernet, Wireless Protocols (Wi-Fi, Bluetooth, Zigbee) |

Hardware forms the backbone of these systems, enabling data collection and physical actions. Software processes this data and provides the intelligence needed for decision-making. Communication technologies ensure seamless interaction between devices, allowing the system to function as a cohesive unit.

In addition to these core components, integrated control solutions often include features like diagnostic tools, safety systems, and compliance mechanisms. For example, they adhere to safety standards such as IEC 61508, ensuring reliability and adherence to regulations. These systems also reduce wiring and panel size, making them more compact and easier to install.

Integrated control solutions operate by connecting various devices and systems into a single, unified architecture. This integration allows you to monitor, control, and optimize processes in real time. Here's how it works:

Data Collection: Sensors and other hardware components gather data from the environment or machinery.

Data Processing: Software analyzes this data, identifying patterns, anomalies, or areas for improvement.

Communication: The system uses protocols like Ethernet or Modbus to share information between devices.

Action: Based on the processed data, actuators or other hardware components perform specific actions, such as adjusting a machine's speed or shutting down a system for safety.

For example, in a manufacturing plant, an integrated control solution might monitor the temperature of machinery. If the temperature exceeds a safe limit, the system can automatically shut down the equipment to prevent damage or accidents. This level of automation reduces the need for manual intervention, improving both efficiency and safety.

Integrated control solutions are already transforming industries worldwide. Here are some notable examples:

Case Study Title | Description |

|---|---|

A water utility client used advanced control systems to improve efficiency and scalability. | |

Rockwell Automation Solutions Improve Spice Company’s Production Capabilities | Automation replaced manual control, increasing throughput and reducing costs in spice production. |

Major SCADA & PLC Upgrade Increases Uptime, Lowers Maintenance Costs for Rice Milling Company | A rice milling company upgraded its PLC system, resulting in improved uptime and lower maintenance costs. |

Implementing a Hybrid SCADA Solution Using PlantPAx 5.0 & 4.10 | A biopharma facility integrated different controllers into a hybrid SCADA solution, enhancing operational efficiency. |

These examples highlight the versatility of integrated control solutions. Whether it's improving production capabilities, reducing maintenance costs, or enhancing scalability, these systems deliver measurable benefits. They also demonstrate how industries are leveraging technology to stay competitive in an increasingly automated world.

Integrated control solutions simplify operations by centralizing control and monitoring. This eliminates repetitive tasks and reduces downtime, leading to smoother workflows. For example, real-time data from these systems allows you to identify inefficiencies and address them immediately. This not only optimizes processes but also increases output.

Here are some key ways these systems enhance efficiency and productivity:

Workflow efficiency improves as tasks are streamlined.

Real-time monitoring ensures better quality control.

Cost reduction becomes achievable through optimized operations.

Compliance and risk management improve with automated checks.

Material waste reduces due to precise control.

Scalability and flexibility allow you to adapt to changing demands.

By leveraging these benefits, you can achieve operational excellence and stay competitive in your industry.

Safety and reliability are critical in any operation. Integrated control solutions enhance both by automating safety protocols and providing real-time alerts. For instance, these systems can detect anomalies, such as overheating machinery, and take immediate action to prevent accidents. This reduces the risk of human error and ensures a safer working environment.

Additionally, these solutions adhere to strict safety standards, such as IEC 61508, ensuring compliance with industry regulations. Reliable systems also minimize downtime, keeping your operations running smoothly. When safety and reliability improve, you gain peace of mind and build trust with stakeholders.

Cost reduction is one of the most significant advantages of integrated control solutions. These systems optimize resource usage, leading to substantial savings. For example, energy consumption can decrease by up to 10%, while chiller maintenance costs may drop by as much as 67%. Over three years, businesses have reported savings of nearly $1.5 million.

Cost Reduction Metric | Value |

|---|---|

Energy savings | Up to 10% |

Reduction in chiller maintenance | Up to 67% |

Savings over three years | Nearly $1.5 million |

Rental premiums | 7% |

Present value of rental premiums | $3.2 million |

Payback period | 8 months |

These savings demonstrate how integrated control solutions not only reduce expenses but also deliver a quick return on investment. By optimizing resources, you can allocate funds to other critical areas, driving growth and innovation.

Integrated control solutions play a vital role in helping businesses scale and prepare for future growth. These systems provide the flexibility and efficiency needed to adapt to changing demands, making them an essential tool for modern industries.

One way these solutions support scalability is by integrating safety-related information into Distributed Control Systems (DCS). This ensures compliance with regulations while improving operational safety and efficiency. For example, modern DCS systems can handle increasing amounts of data without compromising performance. This capability allows businesses to expand their operations without worrying about system limitations.

Another example is the integration of power substation automation systems with DCS. This combination enhances energy efficiency and improves operator effectiveness. As your business grows, energy demands increase. Integrated systems ensure that energy usage remains optimized, reducing costs and supporting sustainable growth.

Additionally, tools that integrate procedural operations streamline process management. Operators can access critical information without distractions, improving decision-making and overall productivity. This feature becomes increasingly important as operations scale, ensuring that processes remain efficient even as complexity grows.

Financial model software also demonstrates scalability by efficiently handling large datasets and complex calculations. When integrated with external systems like accounting software or CRM platforms, it enables seamless data exchange. This integration not only enhances efficiency but also ensures that your business can manage growth without operational bottlenecks.

By adopting integrated control solutions, you can future-proof your operations. These systems provide the adaptability and efficiency needed to thrive in a competitive market. Whether you're expanding production, managing larger datasets, or optimizing energy use, these solutions ensure that your business remains agile and ready for the challenges ahead.

In manufacturing, integrated control solutions revolutionize production lines by automating processes and improving efficiency. These systems connect machinery, sensors, and software to create a seamless workflow. You can monitor operations in real time, identify bottlenecks, and make adjustments instantly. This level of control ensures that production lines operate smoothly and deliver consistent results.

Here are some key improvements you can achieve with integrated control solutions:

Increased productivity by automating repetitive tasks, allowing workers to focus on critical activities.

Reduced operational costs through minimized manual processes and optimized resource usage.

Improved data accuracy by eliminating errors from manual data entry.

Enhanced collaboration as shared data fosters better communication between departments.

Faster decision-making due to quick access to accurate, real-time data.

Streamlined operations by synchronizing systems and eliminating inefficiencies.

Upgraded quality control with early detection of defects, reducing waste.

Higher customer satisfaction through faster production and fewer quality issues.

Easier scalability, enabling you to adapt to production changes and integrate new technologies.

Improved safety by reducing human error and minimizing risks associated with repetitive tasks.

By implementing these solutions, you can transform your production lines into highly efficient and adaptable systems, ready to meet the demands of modern manufacturing.

In healthcare, integrated control solutions enhance patient care and optimize the management of medical equipment. These systems connect devices, software, and data platforms, enabling you to monitor equipment usage, track patient metrics, and streamline workflows. This integration improves both the quality of care and operational efficiency.

Metric | Description |

|---|---|

Medical Equipment Utilization | Measures how effectively advanced medical equipment is used, impacting costs and treatment efficiency. |

Tracks the time patients wait to see a provider, influencing patient satisfaction and operational efficiency. | |

Error Rates | Indicates the frequency of mistakes in patient care, which can affect outcomes and safety. |

Readmission Rates | Reflects the percentage of patients who return for treatment, serving as a quality of care indicator. |

For example, you can use these systems to monitor medical equipment in real time, ensuring it operates efficiently and remains available when needed. This reduces downtime and prevents delays in patient care. Additionally, integrated systems help reduce error rates by automating data entry and providing accurate information to healthcare providers. By improving these metrics, you can deliver better outcomes for patients while optimizing resources.

Integrated control solutions play a crucial role in the energy sector, particularly in managing renewable energy systems. These systems integrate solar panels, wind turbines, and energy storage units into a unified platform. You can monitor energy production, storage, and distribution in real time, ensuring optimal performance and efficiency.

For instance, these solutions allow you to track energy output from solar panels and adjust operations based on weather conditions. They also help balance energy supply and demand by managing storage systems effectively. This ensures that renewable energy sources are utilized to their full potential, reducing waste and lowering costs.

Moreover, integrated systems enhance grid stability by predicting energy fluctuations and responding proactively. This capability is essential as the world transitions to cleaner energy sources. By adopting these solutions, you can contribute to a more sustainable future while improving the reliability and efficiency of energy systems.

Integrated control solutions are revolutionizing the transportation industry by enhancing logistics and fleet operations. These systems allow you to manage fleets more effectively, reduce costs, and improve overall efficiency. By integrating advanced technologies like telematics, AI, and IoT, you can gain real-time insights into vehicle performance and driver behavior, enabling smarter decision-making.

Here are some key advancements you can achieve with integrated control solutions in transportation:

Fuel Efficiency: Monitor fuel consumption patterns to identify inefficiencies and implement strategies that save fuel.

Maintenance Scheduling: Use predictive maintenance to anticipate issues before they occur, minimizing downtime and extending vehicle lifespan.

Driver Performance: Track driver behaviors to improve safety and efficiency through targeted training programs.

Route Optimization: Analyze traffic and road conditions to find the most efficient paths, reducing delivery times and costs while enhancing customer satisfaction.

For example, telematics systems provide real-time data on vehicle performance, allowing you to address potential problems proactively. AI and IoT further enhance this process by collecting and analyzing data at a scale that was previously impossible. These technologies enable you to optimize routes, reduce idle times, and ensure timely deliveries, all while lowering operational costs.

By adopting these solutions, you can transform your logistics operations into a well-oiled machine. Whether you're managing a small fleet or a large-scale transportation network, integrated control solutions provide the tools you need to stay competitive in a fast-paced industry.

In the food and beverage industry, maintaining safety and quality compliance is critical. Integrated control solutions help you achieve this by automating processes, improving efficiency, and ensuring adherence to strict regulations. These systems streamline operations, reduce errors, and enhance product quality, making them indispensable for modern food production.

Metric | Improvement Range |

|---|---|

Productivity Improvement | |

Reduction in Machine Downtime | 30-50% |

These improvements demonstrate how integrated control solutions can significantly boost operational performance. For instance, machine vision systems and AI can detect defects during production, ensuring only high-quality products reach consumers. Clean-in-Place (CIP) automation optimizes cleaning cycles, helping you comply with sanitation regulations while reducing water and chemical usage.

Automated quality management solutions also simplify tasks like document control and corrective actions. This ensures that your processes remain compliant with industry standards and that any issues are addressed promptly. By integrating these systems into your operations, you can reduce downtime, improve productivity, and maintain the highest levels of quality and safety.

Whether you're producing beverages, packaged foods, or perishable goods, integrated control solutions provide the reliability and precision you need. These systems not only help you meet regulatory requirements but also enhance customer trust by delivering consistent, high-quality products.

Artificial intelligence (AI) and machine learning (ML) are transforming how you interact with control systems. These technologies analyze vast amounts of data, identifying patterns and predicting outcomes. This allows systems to make smarter decisions without human intervention. For example, AI can optimize production schedules by predicting equipment failures. ML algorithms can also improve energy efficiency by learning usage patterns and adjusting operations accordingly.

You benefit from these advancements through increased accuracy and reduced downtime. AI-powered systems adapt to changing conditions, ensuring consistent performance. This adaptability makes them essential for industries aiming to stay competitive in 2025.

The Internet of Things (IoT) is revolutionizing integrated control solutions by connecting devices and enabling real-time communication. IoT sensors monitor variables like temperature, pressure, and humidity, providing detailed data for system health assessments. This data allows you to detect faults early and take proactive measures.

Real-time monitoring enhances diagnostics and fault detection.

Learning algorithms optimize energy usage, improving HVAC efficiency.

Continuous monitoring ensures precise control, reducing energy consumption and costs.

IoT transforms traditional systems into intelligent, adaptive networks. For instance, HVAC systems become more efficient, saving energy and lowering your environmental impact. These advancements make IoT integration a game-changer for modern industries.

As integrated control solutions evolve, cybersecurity becomes a critical focus. Cyber threats can disrupt operations and compromise sensitive data. To address these risks, organizations adopt advanced measures like network segmentation and industrial firewalls. These tools protect critical systems and ensure secure data flow.

The Integrated Controls Management (ICM) Model outlines key principles for cybersecurity. These include assigning accountability, maintaining situational awareness, and managing risks proactively. By following these guidelines, you can safeguard your systems against evolving threats.

Patching control systems also plays a vital role in cybersecurity. Creating an asset inventory and testing patches in a controlled environment ensures system reliability. These strategies help you maintain a secure and efficient operation, even as cyber threats grow more sophisticated.

5G and edge computing are transforming integrated control solutions by delivering faster data processing and improved system responsiveness. These technologies work together to reduce latency, enhance reliability, and enable real-time decision-making. You can leverage these advancements to optimize operations and achieve better performance across industries.

5G networks provide high-speed connectivity, allowing devices to communicate instantly. Edge computing processes data closer to its source, eliminating delays caused by transferring information to centralized servers. This combination ensures that your systems respond quickly to changing conditions, improving efficiency and accuracy.

For example, in an automotive plant, integrated control systems powered by 5G and edge computing identify defects in under one second. This reduces inspection times from five minutes, enabling faster production cycles. Emergency services benefit as well, with response times dropping from eight minutes to under three minutes. Faster communication and localized data processing enhance emergency response efficiency, saving lives.

Industry | Benchmark Achieved | Performance Improvement |

|---|---|---|

Automotive Plant | Reduced inspection time from 5 minutes | |

Emergency Services | Response times dropped from 8 minutes to under 3 minutes | Enhanced emergency response efficiency |

Healthcare | Instant access to 3D medical images without data leaving premises | Maintained HIPAA compliance while improving access |

Retail | Real-time detection of suspicious behavior | Saved $50,000 monthly in cloud storage costs |

In healthcare, edge computing enables instant access to 3D medical images while ensuring data remains on-site. This improves access to critical information while maintaining compliance with privacy regulations like HIPAA. Retailers use these technologies to detect suspicious behavior in real time, saving $50,000 monthly by reducing reliance on cloud storage.

By adopting 5G and edge computing, you can unlock new levels of performance in integrated control solutions. These technologies empower your systems to operate faster, smarter, and more efficiently, helping you stay ahead in a competitive landscape.

Integrated control solutions are transforming industries by combining hardware, software, and communication technologies into unified systems. These solutions improve data accuracy, streamline processes, and enhance productivity. They also enable better decision-making and reduce redundancies, making them indispensable for modern businesses.

Key Factors Driving Growth | Description |

|---|---|

Adoption of Industry 4.0 Technologies | Industry 4.0 technologies are driving innovation in integrated control solutions. |

Demand for Enhanced Operational Efficiency | Businesses seek solutions that improve efficiency and reduce costs. |

Integration of Advanced Technologies | AI, machine learning, and cloud computing enable predictive maintenance and optimization. |

The rapid pace of automation and digitization highlights the need for these systems. Smart factories, powered by the Industrial Internet of Things (IIoT), are becoming the norm. By adopting integrated control solutions, you can stay competitive, address workforce challenges, and embrace data-driven strategies.

As 2025 approaches, these systems will play a pivotal role in driving innovation and efficiency. Businesses that invest in them now will position themselves for long-term success in an increasingly automated world.